CAD/BIM/VDC

Featured Projects

We are Vaughn Industries

Capabilities

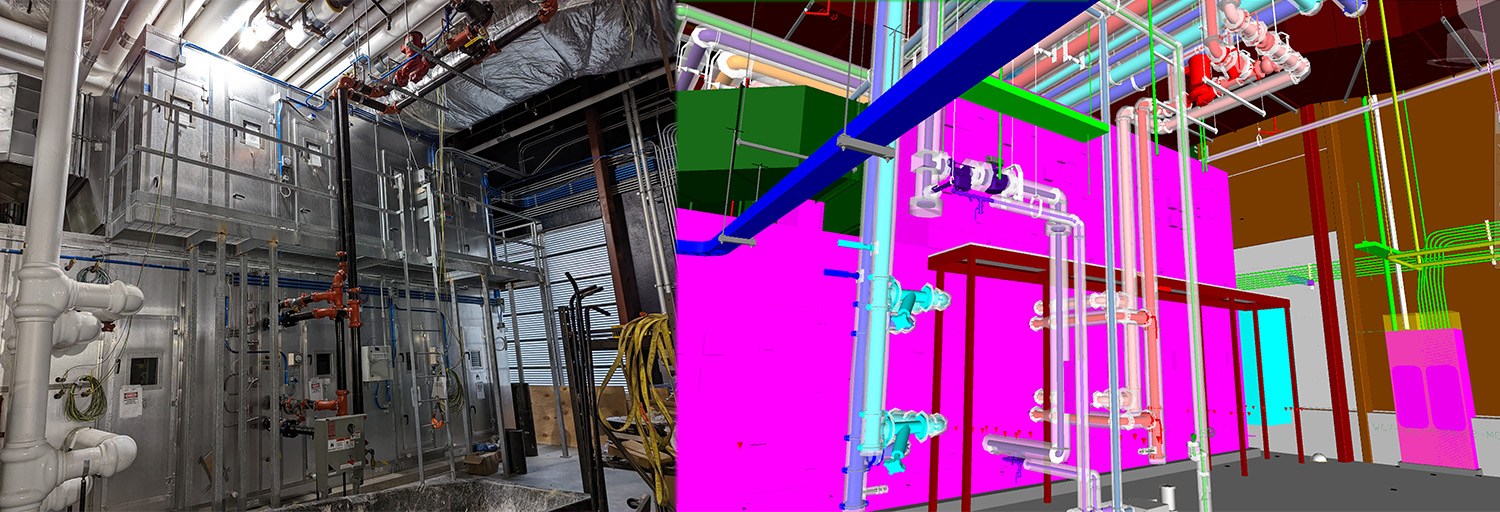

CAD/BIM/VDC (Virtual Design & Construction) allows the designer, contractor and owner to collaborate within the same integrated model. This enables early decision making, better building trade coordination and enhanced project execution.

Utilizing Revit MEP, Navisworks, MEP Fabrication, Greenlee Bendworks, Civil 3D, Map 3D, Inventor, and Trimble Total Station, our in-house CAD/BIM/VDC department can populate, coordinate, and fabricate the MEP aspects of any commercial/industrial project as well as High Voltage and Renewable projects. Taking the base design models from the A&E team, 3D scans, or a traditional set of PDF drawings, the Vaughn Team will generate a 3D model of the project for coordination and fabrication purposes. This process drastically reduces installation time and unforeseen field issues.

MEP Coordination

Our BIM Department coordinators employ Navisworks Manage to identify and resolve conflicts and constructability issues virtually before they become issues in the field. Upon completion of coordination, the model is prepared for fabrication and the system generates installation drawings.

Fabrication files and install drawings are then sent to the VI Prefabrication shop, where the coil line, plasma table, Vernon Pipe Cutter, and Greenlee benders are used to prefabricate a majority of the parts and pieces needed for construction of the project.

3D Scanning

3D scanning is accurate, fast and safe. In as little as 3 minutes, an average scan can capture 130 million points with up to 1/16″ accuracy within 260 feet. With the ability to scan objects up to 1100 ft. away, this technology eliminates the need to enter minimum approach boundaries, eliminates outages, gives real-time access to data & models and increases direct communication reducing design and approval process times.

Vaughn’s 3D scanning capabilities allow us to obtain precise measurements of existing structures quickly and safely. The scan can then be used on its own, or incorporated into a model to assist with prefabrication, safety, preplanning activities, construction sequencing and direct collaboration between the project team and owner.

Custom Design

Whether it’s part of a large scale project or an individual request from a client, the CAD/BIM/VDC Department can design custom items to meet the requirements of the situation. Utilizing Revit, AutoCAD, and Inventor, the Vaughn Team can design everything from small custom parts to large structural platforms and stairs. Once designed, the VI Fabrication shop will take your ideas from virtual design to reality.

From below grade to the penthouse, the VI Trimble Total Station Team always hits the mark. Utilizing the coordinated model and Trimble points from the BIM team, our Trimble team will layout site lights, underground duct banks, utility trenches, MEP Hangers, supplemental support steel, and much more! Utilizing the Trimble Total Station, coordinated locations in the BIM Model become a reality with precision accuracy further eliminating potential installation issues and saving time and money.

Ground Penetrating Radar (GPR)

Staying on the cutting edge of technology, Vaughn invested in a Ground Penetrating Radar unit. This technology allows us to get a visual of what is underground. We can use this to identify issues before even beginning to do dirt work! Utilizing GPR on projects gives us and the owner, the advantage to recognize potential issues and work through the most cost-effective solutions prior to excavating.

- Revit MEP

- Autodesk Civil 3D

- Navisworks Manage

- Autodesk Fabrication

- AutoCAD 3D MEP

- Inventor

- Sheet Metal Modeling

- Hydronic Pipe Modeling

- Plumbing Modeling

- Electrical Modeling

- Greenlee Conduit Fabrication

- Coil Line Sheet Metal Fabrication

- Plasma table exports for duct and custom parts

- Vernon Pipe Cutter Exports

- Revit Families

- Bluebeam

- Procore

- BIM360

- Trimble Total Station Point Layout

- Trimble 3D Scanning Capabilities

- Trimble ground penetrating Radar